Fast and easy for flawless IPS e.max® CAD restorations

The Programat CS2 is a modern crystallization, glazing and ceramic furnace for dental applications that has been specifically developed for use in the dental office. The firing chamber may be heated up to max. 1200 °C by means of a heating element. Furthermore, the firing chamber has been designed in such a way that a vacuum may be created with a vacuum pump. Electronic components with the corresponding software monitor and control the firing programs. Additionally, the set and actual temperatures are continuously compared.

Innovative

The Programat® CS2 has been developed especially for processing IPS e.max® CAD. The furnace renders crystallization and glaze firing in the dental office extremely easy and fast. Designed for simple and intuitive operation, Programat CS2 offers pre-set Ivoclar Vivadent programs and a controlled cooling process.

- Large time-remaining display

- Backup power time of up to 10 seconds in the event of a mains failure

- QTK2 muffle technology with SiC bottom reflector

- Selectable signal tones of the loudspeakers

- Cooling tray accommodating two firing trays

Glaze and crystallization firing. At the push of a button.

Ease of operation

Programat CS2 can be conveniently operated by means of the wide touchscreen colour display. The most important functions, however, are selected via the time-tested membrane-sealed keypad.

OSD display

The optical operating status display (OSD) of the Programat CS2 uses different colours to inform the user about the actual operating status of the furnace (Red = Heating, Green = Ready).

Programat CS2 comes with a range of programs ideally adjusted to IPS e.max CAD materials. Moreover, the furnace is equipped with a controlled cooling phase for the crystallization process.

Further highlights

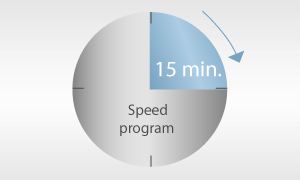

Speed program for IPS e.max CAD

With this program, IPS e.max CAD can be crystallized even faster. This makes the furnace even more cost-effective.

Multi-functional furnace with 20 individual programs

In addition to the pre-set Ivoclar Vivadent programs, Programat CS2 offers 20 individual programs. They are ideally suited for glaze and corrective firing procedures, and for firing procedures involving veneering ceramics.

Firing tongs and integrated tong holder

The firing tongs allow objects to be easily placed in and removed from the firing chamber. When not in use, they conveniently store away in the holder.

Reduced-noise vacuum technology

Due to the new double-valve vacuum technology, the noise level of the vacuum pump is reduced to a minimum. Once the desired vacuum level has been reached, the pump of Programat CS2 automatically shuts down and maintains the vacuum.

ATK2 temperature calibration

The automatic double-range temperature calibration set (ATK2) enables fully automatic temperature calibration in two temperature ranges. This ensures high firing precision and outstanding firing results.

LAN and USB ports

The LAN and USB interfaces permit connection of the furnace to other equipment, e.g. printers, USB flash drives and external hard drives. Software updates can also be performed using a USB flash drive.

Remote diagnostics through the Internet via e-mail

A diagnostic file can be generated at the push of a button if technical support is needed. The file can be conveniently e-mailed to one of the service centres, which will attend to the issue immediately

Technical data

| Power supply | 100 V / 50– 60 Hz 110 – 120 V / 50 – 60 Hz 200 – 240 V / 50 – 60 Hz |

| Overvoltage category | II |

| Contamination level | 2 |

| Acceptable voltage fluctuations | ± 10% |

| Max. power consumption | 14 A at 100 V 12 A at 110 – 120 V 8.5 A at 200 – 240 V |

| Acceptable data for pumps of other manufacturers: Max. output: Final vacuum: | 250 W / max. leakage current 0.75 mA < 50 mbar Only tested pumps should be used |

| Electrical fuses | 100 V or 110 – 120 V: 125 V / T15A (heating circuit) 125 V / T5A (vacuum pump) 200 – 240 V: 250 V / T8A (heating circuit) 250 V / T3.15A (vacuum pump) |

| Dimensions of electrical fuses | 100 V or 110 – 120 V: Diameter 6.3 x 32 mm 200 – 240 V: Diameter 5 x 20 mm |

| Dimensions of the closed furnace Depth: | 465 mm Width: 320 mm / 390 mm (with cooling tray) Height: 320 mm |

| Usable size of the firing chamber | Diameter: 90 mm Height: 80 mm |

| Max. firing temperature | 1200 °C |

| Weight | 15.6 kg |