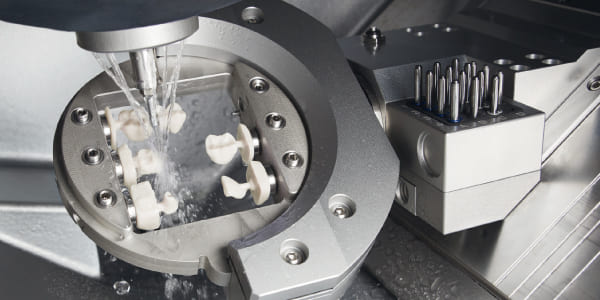

The 5-axis milling machine for non-stop dry and wet machining

With the R5 – a new high-end machine for the dental laboratory – vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a ten-fold blank changer for wet and dry machining. In a minimal footprint, it combines utmost precision with maximum stability and is capable of handling any material.

No material is off limits: discs, blocks, and abutments.

Machinable materials:

- Composites

- Plastics

- Glass ceramics

- Zirconia

- Titanium

- CoCr

Maximum freedom of indication:

- crown

- bridge

- inlay/onlay

- abutment

- telescopic crown

- model plate

- model cast

- occlusal splint

- model tooth

- implant bar

- veneer

- drilling template

- denture

- secondary crown

- screw-retained bridge

- protrusion splint

Just clear water required

For wet machining, the R5 grinds and mills with clear water which you just have to fill into the integrated water tank. For all materials, except titanium, without any additives – better for your materials and without annoying disposal.

Absolute independence

- Sheer unlimited material accessibility in 98 mm disc format, 30 block materials

- > 140 titanium and CoCr prefab abutment platforms

- Covers the broadest range of indications, due to ± 35° rotation angle in the 5th axis, and up to 40 mm blanks

Highly economical

- One of the fastest machines on the market

- Revolutionary material loading with Direct Disc Technology (patent pending)

- Automatic changer holds up to 10 discs, 60 blocks, or 60 prefab abutment blanks

- Direct Clean Technology enables wet and dry on the fly: ionizer, self-cleaning and built-in dryer (patent pending)